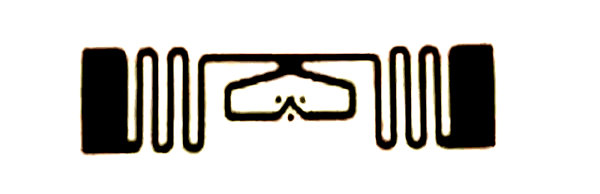

A little smudge of carbon could make a huge difference in wireless Health Tech devices. Researchers at the University of Manchester in England have developed a way to print graphene antennas that could lead to low-cost, flexible antennas for everything from RFID tags to wearable devices. In a paper published Applied Physics Letters, they present a novel production technique.

Graphene is a remarkable material. It is a form of carbon that consists of sheets that are just one atom thick. It is strong, an excellent conductor, but it is difficult (and expensive) to make in large sheets. The Manchester team came up with a way to use an ink that contains microscopic flakes of graphene. They print a shape on paper, which results in a porous jumble of random flakes. They then compress the printed element using rollers, resulting in a layer that is extremely thin and has excellent conductivity.

This process could easily be adapted for screen printing and roll-to-roll (R2R) manufacturing on either paper or plastic substrates. The result could be high-volume, low-cost antenna components that are flexible and highly efficient. This could eventually lead to a network of body sensors that can communicate with each other using very low power, possibly from energy harvesting, that could provide detailed data about a person’s physiology around the clock.